Product Description

Product Description

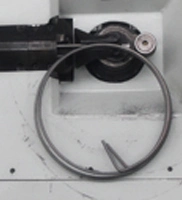

• Automatic wire feeding system ( CNC );

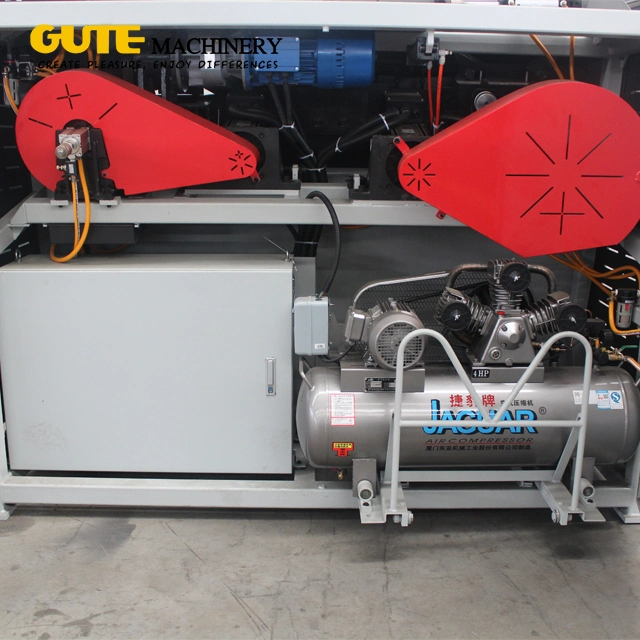

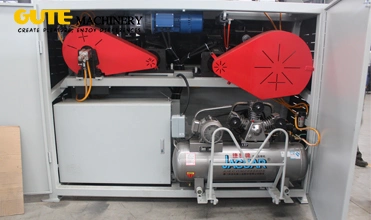

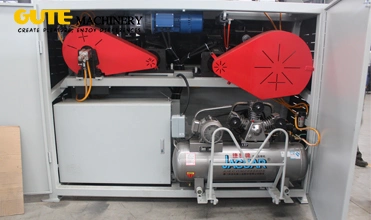

• Moveable air compressor design, to ensure better cooling effect, easy transportation and installation;

• Split, multi-blade design (patented) to reduce consumption costs;

• Large storage capacity can save 500 processing geometric graphics, high degree automation;

• Automatic double wire intake system, high processing efficiency;

• High power feeding motor to ensure bending bar accuracy;

• The intelligent fault identification alarm system maintenance more convenient;

• Aerodynamic design observation door, easy adjustment and maintenance, and more security and fast;

• Touch-screen console, easy to operate, and more fast;

• Service Motor and Control systems: VECTOR(Top 1 brand in China); Electric parts: SIEMENS,SCHNEIDER brand;

SGW12D-1 Parameter | |||

Single Wire Bending Diameter | 5-13mm | Angle Accuracy | ±1° |

Double Wire Bending Diameter | 5-10mm | Maximum Bending Angle | ±180° |

Maximum Traction Speed | 75-100m/min | Longest Stirrup Side | 1000 mm |

Maximum Bending Speed | 800-1050°/sec | Shortest Stirrup Edge | 90 mm |

Total Equipment Power | 33KW | Working Temperature | -5 - 50 ºC |

Average Power Consumption | 5 KW/H | Traction Control Method | servo |

Bending Direction | Double Direction | Bend Control | servo |

Length Accuracy | ±1mm | Total Weight | 3.5 T |

Main Features

1) 1600 stirrups production per hour, each batch can be yield up to 7 tons.

2) The accuracy of ± 1mm, much higher accurate than semi-automatic operation with labor.

3) International brand electric parts were used in machine, which include Simons, ABB and Omron Italian technology applied in the system which ensures the stability of the operation.

4) With the storage of more than 500 hundreds graphics, easy for operation, graphics are programmable.

5) With the option of patented automatic collector, stirrups production will be more efficient and convenient.

PLC Control

Material: Forged alloy

Original: China

It is equipped with 19KW high-power servo motor to ensure the smooth operation of traction. The strength of the square head transition connection is 12 times that of the traditional flat key connection. The traction wheel is made of forged alloy tool steel. It is wear resistant and impact resistant.

Servo Motor

Brand: EURO

Original: China

Chinese Top brand servo motor, high accuracy with high quality.

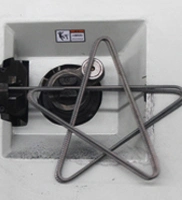

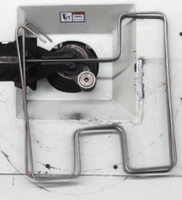

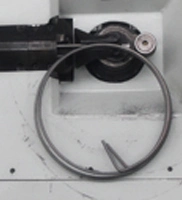

Detail Image

2) The accuracy of ± 1mm, much higher accurate than semi-automatic operation with labor.

3) International brand electric parts were used in machine, which include Simons, ABB and Omron Italian technology applied in the system which ensures the stability of the operation.

4) With the storage of more than 500 hundreds graphics, easy for operation, graphics are programmable.

5) With the option of patented automatic collector, stirrups production will be more efficient and convenient.

Detail Image

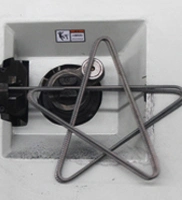

PLC Control

Brand: Kinco

Original: China

Chinese Top brand PLC control system with touch panel, easy for users to input figures.

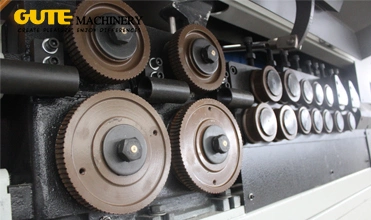

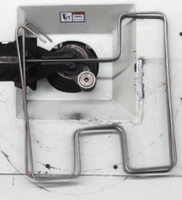

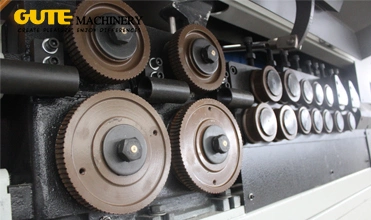

Traction Gear

Material: Forged alloy

Original: China

It is equipped with 19KW high-power servo motor to ensure the smooth operation of traction. The strength of the square head transition connection is 12 times that of the traditional flat key connection. The traction wheel is made of forged alloy tool steel. It is wear resistant and impact resistant.

Servo Motor

Brand: EURO

Original: China

Chinese Top brand servo motor, high accuracy with high quality.

Detail Image