Hunan Gaohua New Materials Technology Co., Ltd

* Product Description

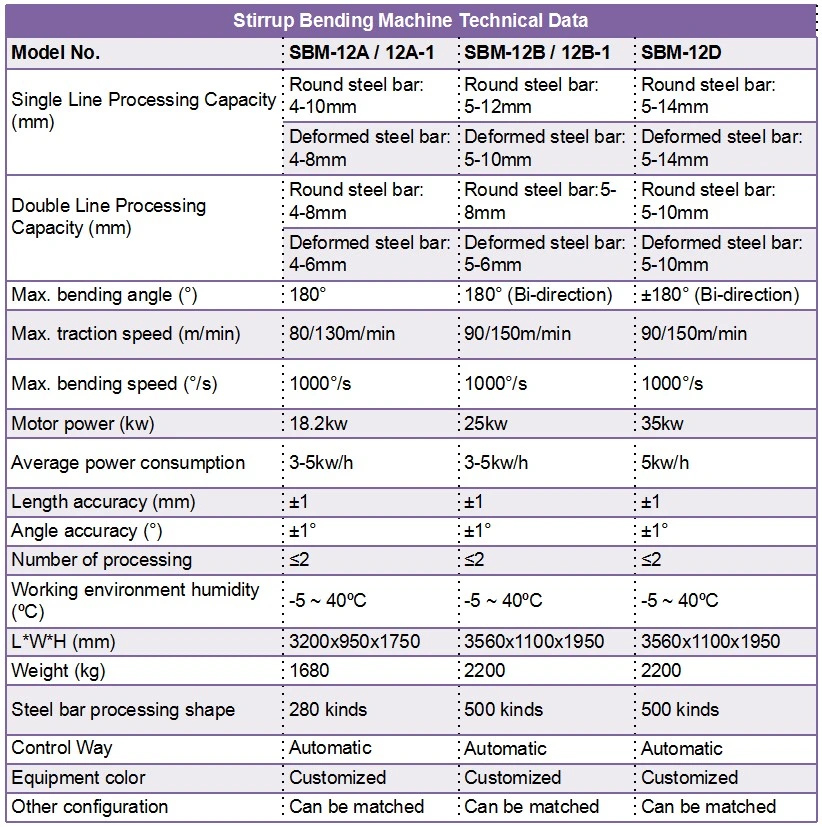

| Stirrup Bending Machine Technical Data | |||

| Model No. | SBM-12A / 12A-1 | SBM-12B / 12B-1 | SBM-12D |

| Single Line Processing Capacity (mm) | Round steel bar: 4-10mm | Round steel bar: 5-12mm | Round steel bar: 5-14mm |

| Deformed steel bar: 4-8mm | Deformed steel bar: 5-10mm | Deformed steel bar: 5-14mm | |

| Double Line Processing Capacity (mm) | Round steel bar: 4-8mm | Round steel bar: 5-8mm | Round steel bar: 5-10mm |

| Deformed steel bar: 4-6mm | Deformed steel bar: 5-6mm | Deformed steel bar: 5-10mm | |

| Max. bending angle (°) | 180° | ±180° (Bi-direction) | ±180° (Bi-direction) |

| Max. traction speed (m/min) | 80/130m/min | 90/150m/min | 90/150m/min |

| Max. bending speed (°/s) | 1000°/s | 1000°/s | 1000°/s |

| Motor power (kw) | 18.2kw | 25kw | 35kw |

| Average power consumption | 3-5kw/h | 3-5kw/h | 5kw/h |

| Length accuracy (mm) | ±1 | ±1 | ±1 |

| Angle accuracy (°) | ±1° | ±1° | ±1° |

| Number of processing | ≤2 | ≤2 | ≤2 |

| Working environment humidity (ºC) | -5 ~ 40ºC | -5 ~ 40ºC | -5 ~ 40ºC |

| Dimension L*W*H (mm) | 3200x950x1750 | 3560x1100x1950 | 3560x1100x1950 |

| Weight (kg) | 1680 | 2200 | 2200 |

| Steel bar processing shape | 280 kinds | 500 kinds | 500 kinds |

| Control Way | Automatic | Automatic | Automatic |

| Equipment color | Customized | Customized | Customized |

| Other configuration | Can be matched | Can be matched | Can be matched |

We also have other models of this type CNC automatic rebar bender / stirrup bending machine, please tell us your rebar information, so that we can quote you the right model of our machine accordingly.

Fully automatic CNC bending and ribbing machine production equipment, can be used for slab length of 12 meters, one machine can be used.

1. The automatic wire feeding system has high structural precision.

2. The numerical control system has high precision and small error.

3. Engineering slope design, not chaotic, straightening efficiency.

4. Using PLC intelligent control, can process a variety of sizes and specifications of polygons.

5. From the wire rod raw material to the stirrup product once formed, can process cold and hot rolled high-strength wire rod steel.

6. High production efficiency, quite 20 to 30 labor.

7. The equipment is highly usable and requires only one person to operate, saving a lot of labor.

8. Saving raw materials, in the work is continuous molding almost no loss of steel head.

9. Equipment maintenance costs and energy consumption costs are very low.

10. This machine is equipped with a ribbed receiving frame, and the size can be customized according to user requirements.

11. The product is stable, high in efficiency and fast in straightening speed.

Package: Packed by wooden case.

Shipment: By sea, LCL or FCL.

* Our Services

1. We will provide the after- service support for all the customers.

2. If the customer needs, we will assign the engineers to provide technical support on site.

3. Implement the first responsibility system with warm reception, and must answer all questions.

4. Provide technical consultation on material selection and use, and follow up on site as required.

5. The delivery accuracy of the goods is 100%, and the goods code, invoice and warranty are processed

according to the requirements of the customers and timely delivered to the customers.

6. Follow up user's product usage, provide technical support and training in time.

* FAQ

Q: Are you trading company or manufacturer ?

A: We are manufacturer. Our factory address is Baoqing industrial concentration district, Shaoyang city, Hunan province, China.

Q: How long is your delivery time?

A: Generally it is 10 days if the goods are in stock. or it is 10-25 days if the goods are not in stock, it is according to quantity.

Q: What is your terms of payment ?

A: Payment<=3000USD, 100% in advance. Payment>=3000USD, 30% T/T in advance ,balance before shipment.

Q: Can you provide installation service?

A: We can provide installation service, but you need pay for the air tickets, hotel, food and 50 USD/ day.

If you have any question , please feel free to contact with me.